High-Precision Machine Guidance Is Going Mainstream in Ellatzite-Med

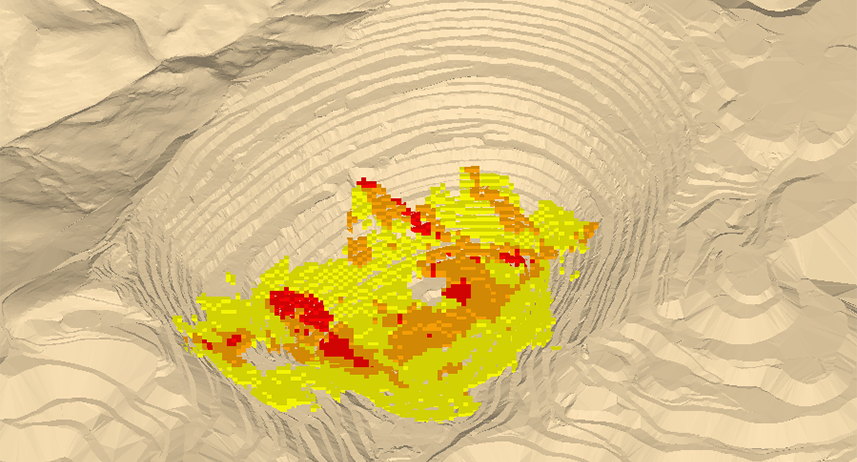

In order to achieve even higher efficiency of the production process, Ellatzite-Med AD continues to upgrade the Dispatch® Fleet Management System, which has been operating efficiently in Ellatzite Mine since 2015. In 2016, the ProVision® system, also a product of Modular Mining Systems, Inc., USA, was deployed and integrated on the territory of the mine. This is a GPS positioning system with 0.1 m accuracy, which uses the location of any machine – an excavator or a drill rig – to determine its activity.

Location tasks are delivered electronically in a suitable work format directly to the ProVision® database by engineers and specialists. When performing the location tasks, all completed actions and the final result are recorded on the database, e.g. the exact drilling, the excavating of the material within the limits, the achieved level of the mining bench, etc. The excavators in Ellatzite Mine are equipped with high-precision GPS receivers and platform inclinometers for determining the excavator inclination axis. For the drill rigs, an inclinometer is added to the drill tower, which accurately determines the azimuth of drilling.

‘Using these technologies, Ellatzite-Med AD has managed to achieve 99% precision in making the wellheads, as well as reducing the drilling depth offsets with 50%,’ said M.Eng. Mladen Nedkov, Deputy Director of ICT Department at Ellatzite-Med AD.

By achieving the indicated drilling accuracy, the costs of unnecessary drilling have been reduced and the effectiveness of blasting operations has increased – the blasted linear meters of drilling per cubic meter of mining mass are 9.8% less than those in 2016 and 2017.

For the excavators, besides the accurate execution of excavating homogenous blocks tasks, the new ProVision® system has also achieved a 0.05 m. average deviation from the design cut-off height, according to the data obtained from surveying measurements. This can be considered as an absolutely accurate implementation of the technological assignment, which reduces the costs of iterated excavation and dumping on already completed work sites.

Continuous monitoring and control of the entire production process is performed by a mining dispatcher in a control centre. All other engineers and specialists in the company, who are involved in controlling the performance of the above tasks, may at any time perform control, adjustments and additions to the technological assignments. The implementation of Dispatch® and ProVision® is one of the examples of the ongoing substantial investments in modern technologies for increasing the use of automation and improving resource efficiency in Ellatzite-Med AD.

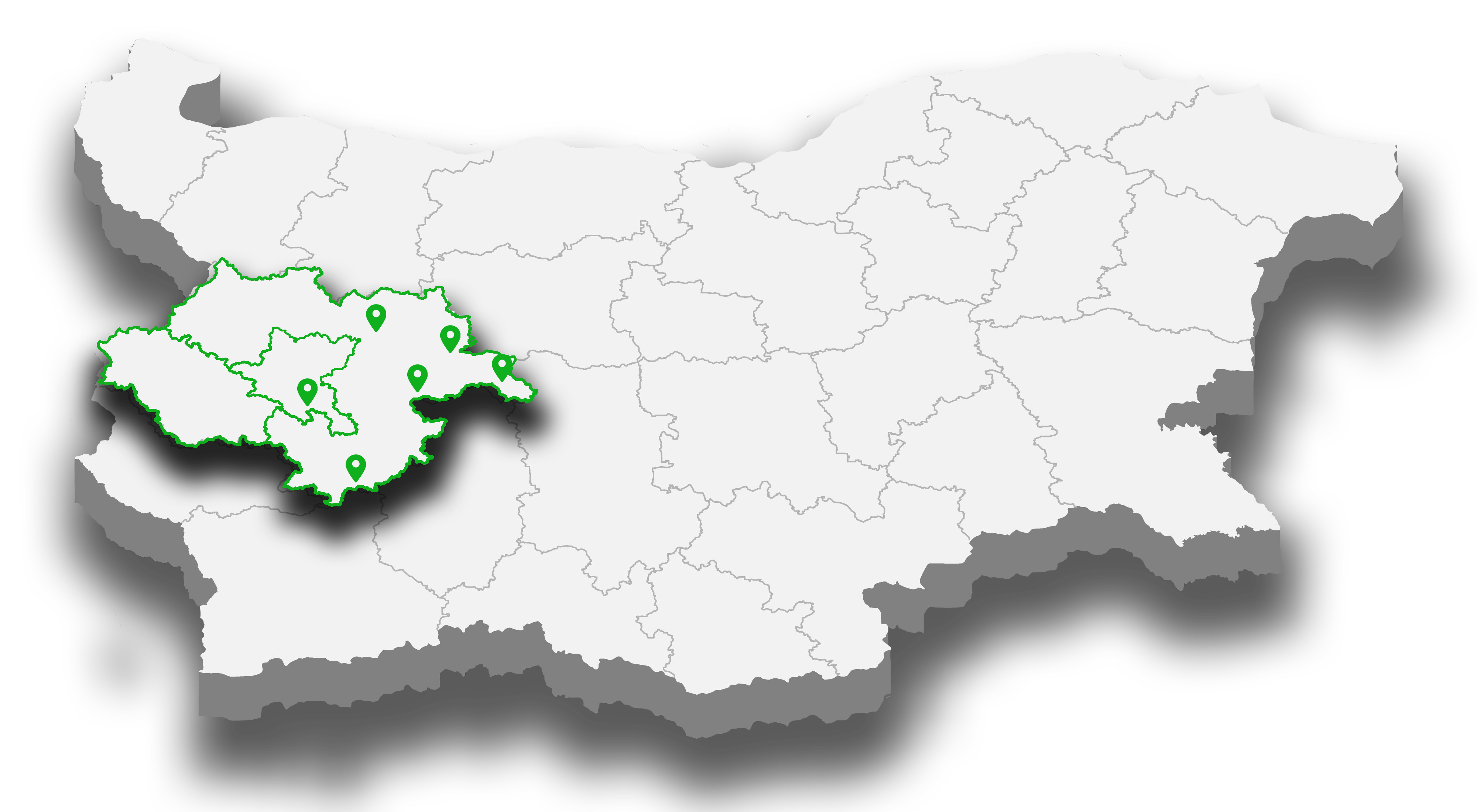

Employer:

Ellatzite-Med ADContractor:

Ellatzite-Med AD and Modular Mining Systems, Inc., USAProject implementation period:

October 2015 – October 2016Date:

June 2023